Projects

Robotic Car Design

-

Designed and fabricated a robotic car capable of traversing ramps and flat surfaces.

-

Programmed a Raspberry Pi and processed http requests using Flask.

-

Used HTML/CSS, JavaScript to create a webpage for users to control the car over the internet.

Challenges:

-

Maintaining a constant IP address of the Raspberry Pi.

-

Creating smooth, and easily controllable turning.

-

Providing sufficient torque to the car wheels without wall outlet access.

Lessons Learned:

-

Incorporated HTML/CSS and JavaScript.

-

Used voltage divider to provide necessary voltages to microcontrollers and motors.

BLACK+DECKER Drill Product Teardown/Redesign and CAD Modeling

-

Examined use cases, concept of operations, and workflow of the product.

-

Modeled relevant parts in SolidWorks to match drill

-

Redesigned drill for Cerebral Palsy client using risk matrices and weighted down selection.

Challenges:

-

Creating SolidWorks models of shapes with unique curvature and profiles.

-

Simplifying use requirements, without altering product feel or appearance.

Lessons Learned:

-

Worked with client in order to better understand design specifications.

-

Recreated product CAD model without engineering drawings/dimensions.

Stepper Motor Gear Train

-

Modeled a gear train to increase a stepper motor's output torque and decrease its output speed using OnShape.

-

Fabricated gear train and housing using 3D printers and laser cutting.

-

Programmed a Raspberry Pi to precisely control stepper motor.

Challenges:

-

Meshing gears together.

-

Accounting for tolerances in 3D printed parts.

Lessons Learned:

-

Focused on gear train math in order to keep pitch constant between gears (allowed for gear meshing).

4 Bar Linkage - "Auto-Pie"

-

Designed a 4 bar linkage system, linkage/stepper motor housing, and "pie-holder" using OnShape.

-

Fabricated components using 3D printers and laser cutting.

-

Programmed a Raspberry Pi to precisely control stepper motor.

Challenges:

-

Keeping 4 bar linkage weight low.

-

Providing enough torque to the linkage system.

-

Restricting motion of 4 bar linkage into 1 plane.

Lessons Learned:

-

Designed CAD models with intention of lowering part weight.

-

Laser cut bearings and spacers in order to keep linkage movement 2D.

Line Follower (Color Sensor)

-

Used a color sensor to autonomously navigate a maze by following a specific color path.

-

Programmed a Raspberry Pi using PID control to maintain correct path along colored paths.

-

Fabricated chassis and wheels using 3D printers and laser cutting.

Challenges:

-

Consistency of color sensor readings.

-

Providing sufficient light to color sensor.

-

Finding the correct balance of proportional, integral, and derivative control in the overall PID controller.

Lessons Learned:

-

Focused on PID control to precisely control motion of a robot.

-

Used color sensor Python libraries.

-

Introduced to i2c controls within microcontrollers.

Airtable Controlled Create 3 Maze Navigation

-

Programmed a Raspberry Pi to communicate with the Create 3 over ROS2.

-

Controlled a Create 3 robot’s movements by publishing and subscribing to the “/cmd_vel” topic in. combination with the geometry message type “Twist”.

-

Used Airtable to request values that were input to publisher nodes.

Challenges:

-

Reading API key values so that they can be published to a topic.

-

Publishing values correctly such that they can be read by the topic.

-

Limited access to information on ROS2 topics.

Lessons Learned:

-

Used ROS2 to publish and subscribe to pre-existing topics.

-

Requested API values from Airtable in Python.

Autonomous Image Recognition Maze Navigation

-

Programmed a Raspberry Pi to communicate with the Create 3 over ROS2.

-

Published to Create 3 ROS2 topics "cmd_vel" and "cmd_audio" to control movement and audio of the Create 3.

-

Trained a model using Google's Teachable Machine to recognize objects through a Raspberry Pi Camera.

Challenges:

-

Slow Raspberry Pi run time limited iteration capabilities.

-

Raspberry Pi Camera field of view is small, making it challenging to view objects.

-

Recognizing objects at a desired distance from the robot.

Lessons Learned:

-

Published to the "cmd_audio" ROS2 topic using the "AudioNoteVector" message.

-

Processed Raspberry Pi Camera images to an image recognition model.

-

Used model outputs to control publishing to ROS2 topics on the Create 3.

Autonomous Smoothie Cafe

-

Designed and fabricated components for "processing" and "blending" stations of cafe.

-

Managed interactions with sponsors to integrate components into the overall project.

-

Presented the smoothie cafe at the 2023 Robotics Summit & Expo.

Challenges:

-

Communication between project teams.

-

ROS2 compatibility with iRobot Create3 robots.

-

Managing budget.

-

Limited access to metal working machines.

Lessons Learned:

-

Planning project scope such that goals are achievable.

-

Communication between teams at all stages of a project is critical for success.

-

Ensuring that others can follow your design process and can operate your creation.

Carbon Fiber Composite Baseball Bat

-

Created a carbon fiber/epoxy layup to be wrapped around a 3D printed baseball bat mold, resulting in a carbon fiber composite baseball bat.

-

Compared swing tests with ANSYS force simulations.

Challenges:

-

Limiting creases in the carbon fibers during the vacuum bagging process.

-

Maintaining constant carbon fiber orientation within each layer.

-

Preventing weak points in the final laminate due to lack of epoxy or carbon fibers in certain areas.

-

Creating ANSYS simulations that represented the true loading conditions.

Lessons Learned:

-

Learned how to make complex geometries from composites.

-

Worked with ANSYS to replicate real life loading condition.

Corn Hole Made from Repurposed Bike Parts

-

Fabricated a corn hole set using bike parts and scrap steel.

-

Cut bike parts using the portable bandsaw.

-

Used TIG welding to make frame and legs of the corn hole set.

Challenges:

-

Finding bikes that were made from steel, not aluminum, so that they could be TIG welded.

-

Removing paint from bike parts to avoid toxic fumes during welding.

Lessons Learned:

-

Improved TIG welding skills.

-

Used new techniques to prepare bike parts such as the portable band saw and angle grinder.

Multi-Sample HTS Test Probe

-

Designed a multi-sample high temperature superconductor (HTS) test probe to make HTS tape characterization more efficient.

-

Created CAD models, CAD drawings, and bill of materials for several designs.

-

Collaborated with other engineers to meet design requirements surrounding cryogenic capacity, material selection, and energy loss minimization.

Challenges:

-

Material/product behavior at cryogenic temperatures

-

Optimization of ohmic losses and convective heat transfer across a temperature gradient.

-

Minimization and repeatability of contact resistances

-

Designing for manufacturability in a small, technologically limited machine shop.

-

Part lead time.

-

Limited prior knowledge about cryogenics and superconductivity.

Lessons Learned:

-

Designing for product robustness and reliability.

-

Deeper knowledge of material property dependence on temperature.

-

Fundamental understanding of cryogenic design and superconductivity.

-

Worked closely with machinists to make CAD drawings and bill of materials.

Automated Clothes Tagging System

-

Designed a system to improve upon the current manual tagging system for clothing identification in order to maximize efficiency and worker safety for immediate integration at Goodwill.

-

Created CAD models, CAD drawings, and a bill of materials for various prototypes.

-

Contributed to fabrication, mechanical analysis, and electrical/coding components of each prototype.

Challenges:

-

Geometric tolerancing on small, custom made parts.

-

Designing for reliability.

-

Preventing overheating of motors and drivers.

-

Handling of flexible materials (fasteners, tags).

Lessons Learned:

-

Collaboration with other engineers for a long term project.

-

Incorporating client requests into prototype design.

-

Limitations of 3D printing for part fabrication.

-

Managing budget.

-

Designing for ease of assembly, usability.

Current Distribution Modeling in Superconducting Transmission Lines

-

Created a foundational circuit model for current distribution within a high temperature superconductor (HTS) cable.

-

Conducted an independent literature review on HTS circuit modeling.

-

Worked with Tufts University professors and professional engineers to review circuit analyses.

Challenges:

-

Minimizing necessary calculations while providing accurate results.

-

Acquiring data for testing model validity.

-

Reviewing large quantities of relevant papers and textbooks.

Lessons Learned:

-

Reviewed electrical engineering principles.

-

Learned the importance of simplifying mathematical models to reduce simulation time and required computational power.

-

Conducted complex AC circuit analysis using mesh current method.

Iron Man Hand Lamp

-

Fabricated a lamp using sheet metal and sheet metal bending.

-

Utilized a water jet, a bending brake, and a spot welder to manufacture and assemble the lamp.

-

Modeled the bends using Solidworks sheet metal tools.

Challenges:

-

Accurately bending sheet metal by hand.

-

Limits on the weld thickness using a spot welder.

-

Designing for assembly.

Lessons Learned:

-

Adding relief cuts to make sheet metal bending easier and to improve bend quality.

-

Understand your materials’ properties well before designing.

-

Consider how the product will be manufactured and assembled, not just the final product’s function.

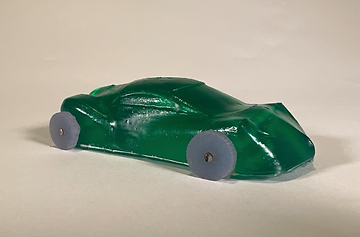

Toy Race Car

-

Used urethane casting to produce a toy race car.

-

3D printed wheels and a chassis to serve as the master in the mold creation process.

-

Fabricated a hard chassis and rubbery wheels from various urethane resins.

Challenges:

-

Minimizing voids and large air pockets in the casting process.

-

Completing casts for parts with small thicknesses and unique geometries.

-

Avoiding undercuts to ensure that the mold is reusable.

Lessons Learned:

-

Tilting the mold during resin curing can improve final part quality.

-

High amounts of part detail can be easily replicated using urethane casting.

-

Simplify part geometry to reduce undercuts and improve mold lifespan.

Puzzle Table

-

Manufactured a flat-pack assembly style table using a CNC router.

-

Designed the puzzle table to use only non-permanent joints such as slot, lap, and housing joints.

-

Utilized VCarve to generate various CNC toolpaths.

Challenges:

-

Machining both sides of a piece of stock, leading to tolerancing issues.

-

Fastening the stock without impeding the cutting tools.

-

Limited sketching capabilities in VCarve.

Lessons Learned:

-

Learned how to program and preview toolpaths on a CNC router using VCarve.

-

Simplify your geometry to avoid requiring excessive material removal.

-

Consider the available cutting tools in your initial design.

Harry Potter Wand

-

Machined a custom Harry Potter wand on a manual lathe.

-

Experimented with several lathe fabrication methods such as turning, knurling, parting, and radius forming tools.

-

Managed lathe rpm based on workpiece material for optimal results.

Challenges:

-

Manually feeding on a lathe produces inconsistencies in surface finish and part quality.

-

Fastening the workpiece during machining to prevent chattering and deflection.

-

Control wheel backlash resulted in difficulty making precisely measured turns.

Lessons Learned:

-

Learned how to set up and machine parts using a lathe.

-

Use additional fixtures to completely fasten the workpiece during machining.

-

Understood how to select appropriate feeds and speeds based on workpiece material.